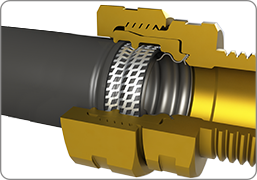

XR3 Fitting Assembly

The cut end of FlashShield CSST must be properly prepped prior to attaching the XR3 fitting. This means removing all 3 jacket layers to the 2nd corrugation, then removing only the outer jacket layer back to the 4th corrugation. The easiest way to do so correctly is by using the Jacket Stripping Tool. This will ensure the metal locking feature of the XR3 will create electrical continuity throughout the system.

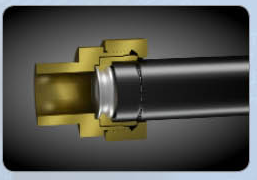

FlashShield Fitting Assembly

The FlashShield fitting assembly procedure is identical to the traditional Gastite fitting assembly procedure, An important distiction however, is that with the FlashShield fitting, the jacket biting feature between the bushing and jacket must be incorporated during assembly. This provides electrical continuity and allows the product to perform as designed. The jacket must be cut back to the valley of the second corrugation and be captured by the biting ring of the split bushings.

The FlashShield fitting assembly procedure is identical to the traditional Gastite fitting assembly procedure, An important distiction however, is that with the FlashShield fitting, the jacket biting feature between the bushing and jacket must be incorporated during assembly. This provides electrical continuity and allows the product to perform as designed. The jacket must be cut back to the valley of the second corrugation and be captured by the biting ring of the split bushings.