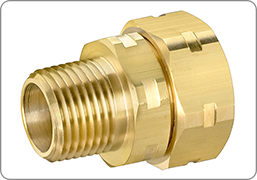

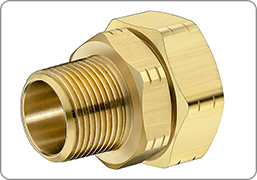

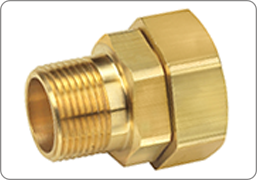

XR3 vs FlashShield vs XR2 Fittings

Appearance

The quickest way to tell the difference between the XR3, FlashShield and XR2 fittings are by the notches on the hex corners. The XR3 fittings have a large flat notch; the FlashShield fittings have 2 thin notches, and the XR2 fittings do not have any. All of the fittings are made from brass components with no O-rings, or gaskets.

XR3 fittings are designed with a patent pending metal locking feature that contours the FlashShield inner metal shield layer, which creates enhanced electrical continuity throughout the system.

XR3 fittings are designed with a patent pending metal locking feature that contours the FlashShield inner metal shield layer, which creates enhanced electrical continuity throughout the system.

FlashShield fittings are designed with a patented Jacket-Bite™ feature that bites through the FlashShield CSST’s first layer of semi-conductive polymer into the inner metal shield, which creates electrical continuity throughout the system. FlashShield fittings can be used on both Gastite yellow and FlashShield CSST.

FlashShield fittings are designed with a patented Jacket-Bite™ feature that bites through the FlashShield CSST’s first layer of semi-conductive polymer into the inner metal shield, which creates electrical continuity throughout the system. FlashShield fittings can be used on both Gastite yellow and FlashShield CSST.

XR2 fittings are exclusively for use with Gastite yellow CSST. They are designed with a patented Jacket-Lock™ that grips the polyethylene jacket eliminating exposed stainless steel beyond the nut.

XR2 fittings are exclusively for use with Gastite yellow CSST. They are designed with a patented Jacket-Lock™ that grips the polyethylene jacket eliminating exposed stainless steel beyond the nut.